Engineering shaft collars

In looking at mechanical fasteners like shaft collars there are different elements to keep in mind and reasons to choose one style above another. You also might be wondering if you should replace existing collars and what is involved in the use of different designs?

Here's a guide to help you review what kind is needed for you.

The Set screw style engineering shaft collars

Screw collars are used primarily online shafting in manufacturing mills. These early shaft collars have protruding screws that can cause problems like catching on clothing while rotating on a shaft, and pulling them into the machinery.

Now we have safety set collars with hex socket head set screws as an industry standard. The invention of the safety set shaft collars was the beginning of the recessed-socket screw industry used today.

We have loads of different kinds of shaft collars to choose from. When using the set screw collars, they work best when the material of the shaft is softer than the set screw. Keep in mind, the set screw will cause an impression damage with a flare-up of shaft material that makes the collar harder to adjust or remove. To eliminate this problem you can machine small flats onto the shaft at the set screw locations. For greater flexibility and avoidance if shaft damage or the need to machine any alterations to the shaft clamp-style shaft collars are best.

Register an account with us today

or call us on +44(0)1384 634461

Clamp-style shaft collars

If your looking for Clamp-style shaft collars, designed to solve the problems associated with the set-screw collar, we can help. They are manufactured in one-piece or two-piece designs. The screws are used to compress the collar and lock it into place, keeping the screws from protruding into the shaft. This design makes it easier to maintain and helps to avoid any shaft damage. With the screws compressing the collar its self, the force is distributed uniformly around the shaft, giving an increase of nearly twice the holding power of set-screw collars.

One-piece shaft collars

Clamp-type collars can work very well under relatively constant loads, but their one-piece design can have restrictions. When used in conditions are not statically or gradually applied loads, one-piece designed clamps can move position on the shaft. If the loading pressure will have points of shock. To be more resistant to shock loads, an undercut can be made on the shaft with a clamp collar used to create a positive stop.

Order one-peice shaft collars

or call us on +44(0)1384 634461

Our two-piece clamp-style engineering shaft collars

Increased performance and flexibility of use

The most innovative, useful and dependable of shaft collars is the two-piece clamping collar. Our two-piece clamp-style shaft collars can be disassembled or installed in position without having to remove other components from the shaft. The two-piece design provides greater clamping force than a single piece clamp because all of the force is transferred directly into clamping the shaft. In single piece collar designs, the side not used to tighten the collar must be open to allow it to be placed onto the shaft, providing the negative force. If only a single tightened it must work against the negative force as well as clamping onto the shaft.

Order two-piece shaft collars

or call us on +44(0)1384 634461

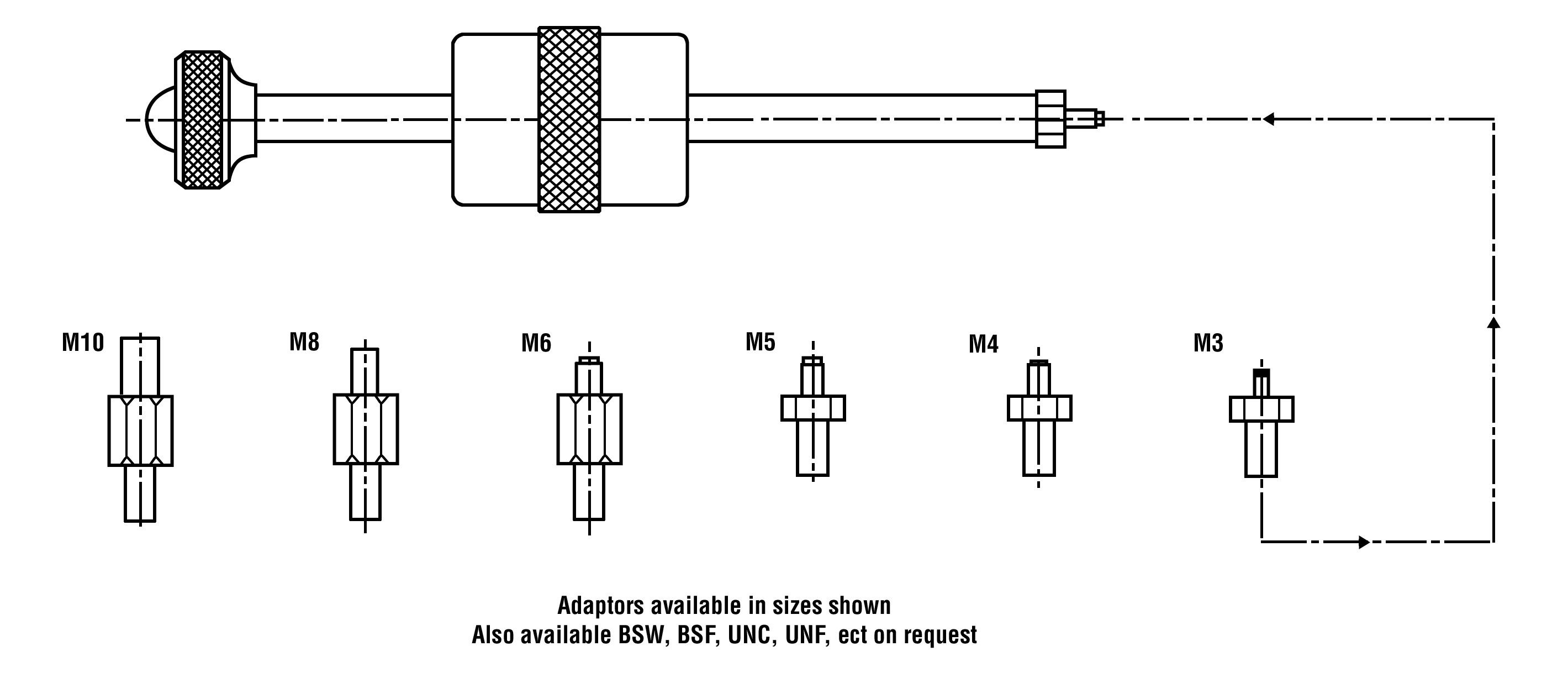

Two-screw clamps provide force on two sides where four screw clamps provide force on four sides giving a more evenly distributed force.